Precision engineering for the injection moulding industry

Plastic injection moulding is used to produce plastic parts in a wide range of sectors such as the automotive, cosmetics and connector industries.

Our parts are designed to be inserted into plastic assemblies.

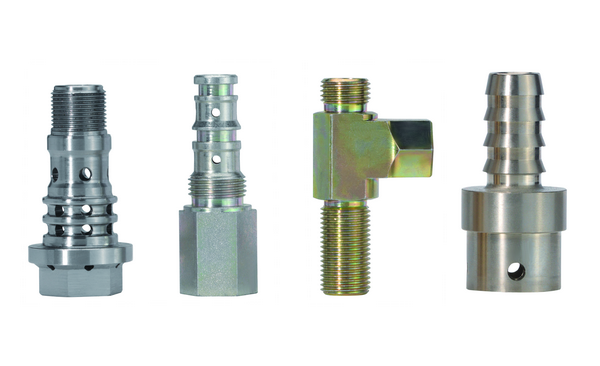

As a manufacturer of parts for the plastic injection industry, we offer subcontracting of machined parts.

Ø3mm to Ø30mm or more

500 to 200 000 parts

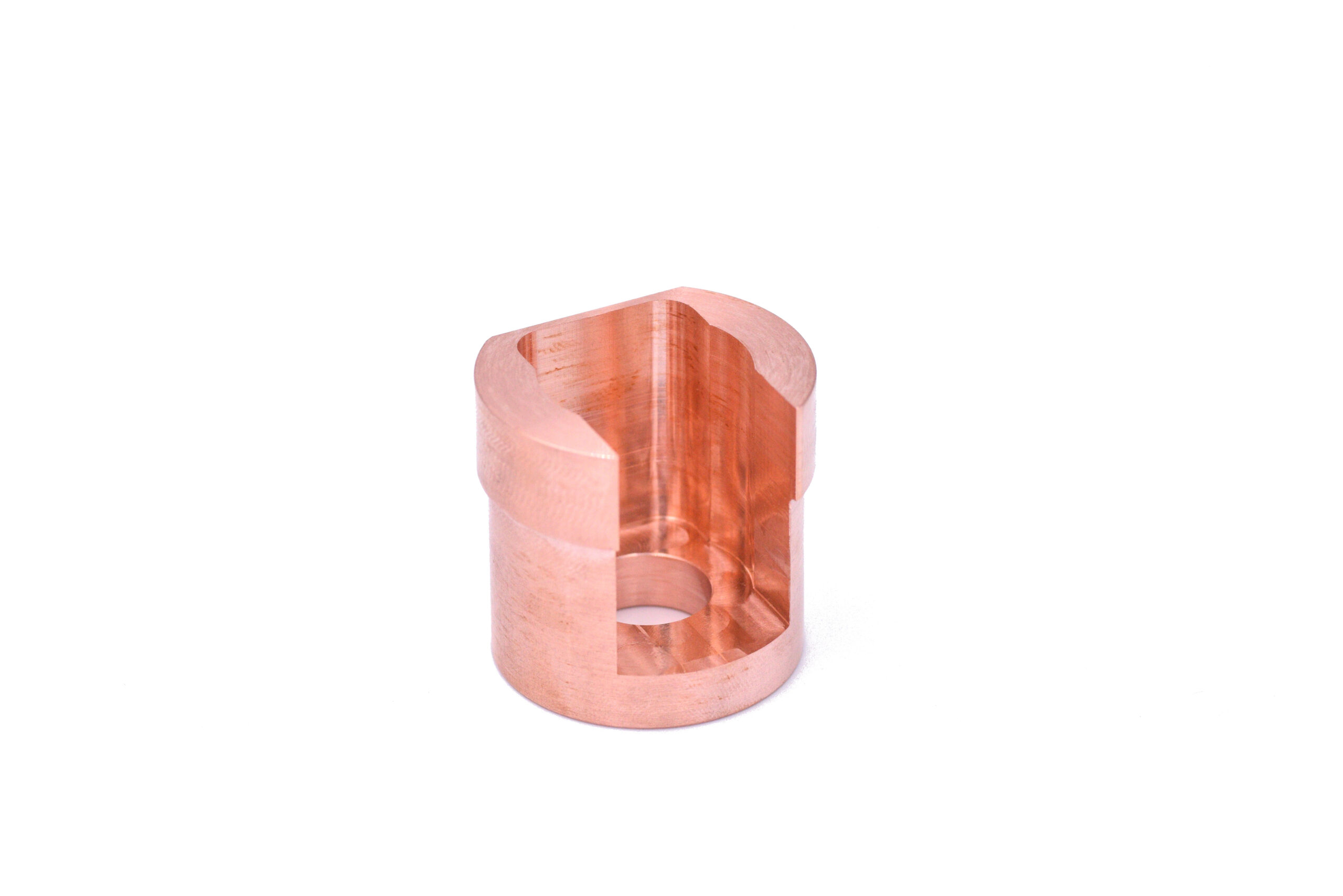

Steel, brass, copper

Machined parts for the plastic injection industry

Our machine fleet enables us to meet all your requirements, from medium to large batches (from 500 to 200,000 parts and more).

Our parts are mainly produced on our high precision CNC sliding headstock machines.

The types of parts machined in our workshop for plastic injection moulding :

- Knurled or hexagonal inserts

- Pickled inserts

- Threaded inserts or inserts with high precision bores

Additional associated services

We carry out broaching directly on our machines (and as a subcontractor according to your specifications).

We are able to offer you tapping operations by deformation directly on our machines.

Machined materials for the plastic injection industry

Additional services for your plastic injection mould machining projects