Turning of parts for the connectivity sector

Ø5 mm Ø36mm or sometimes up to 80 mm and more upon demand

500 to 20 000 parts and more

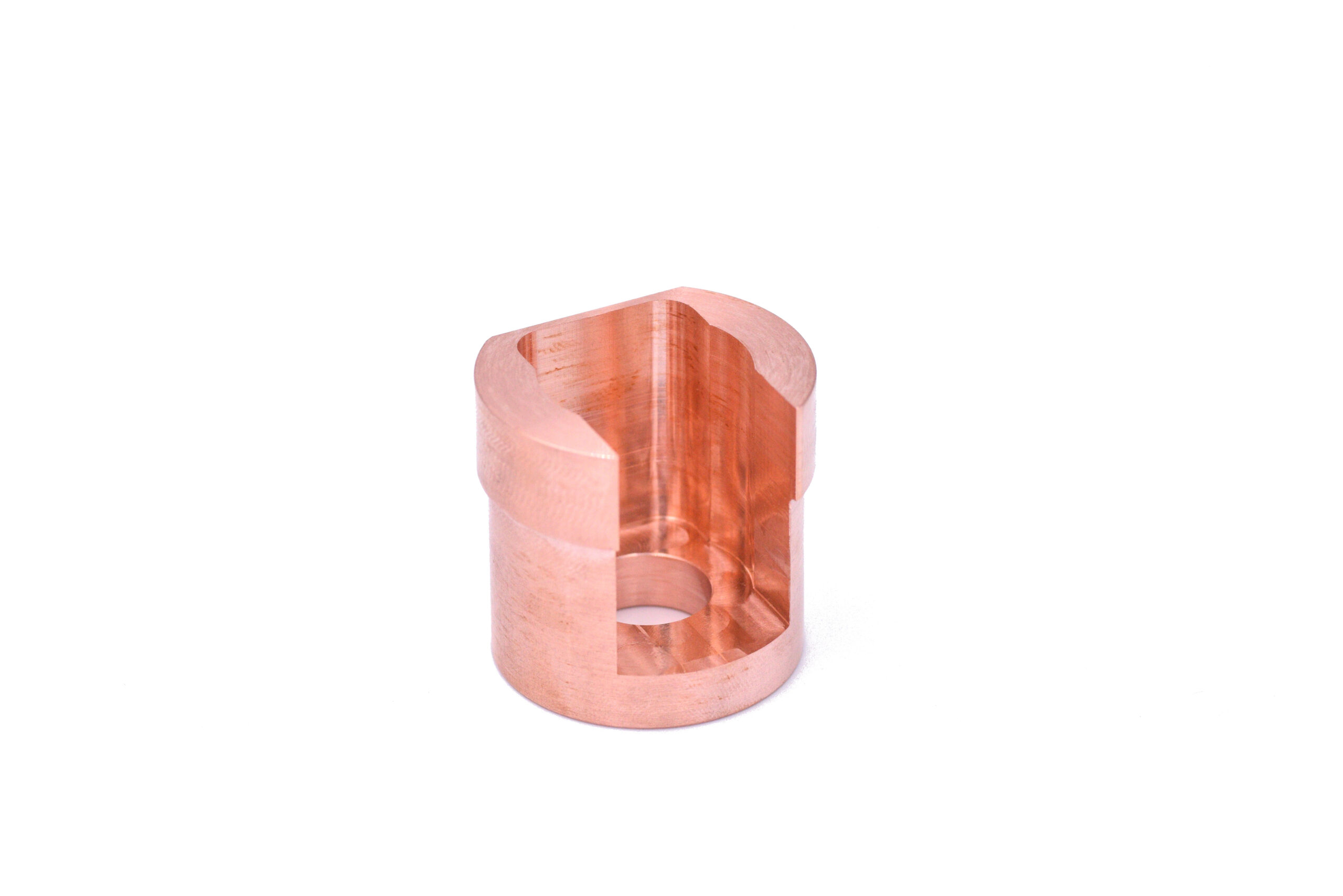

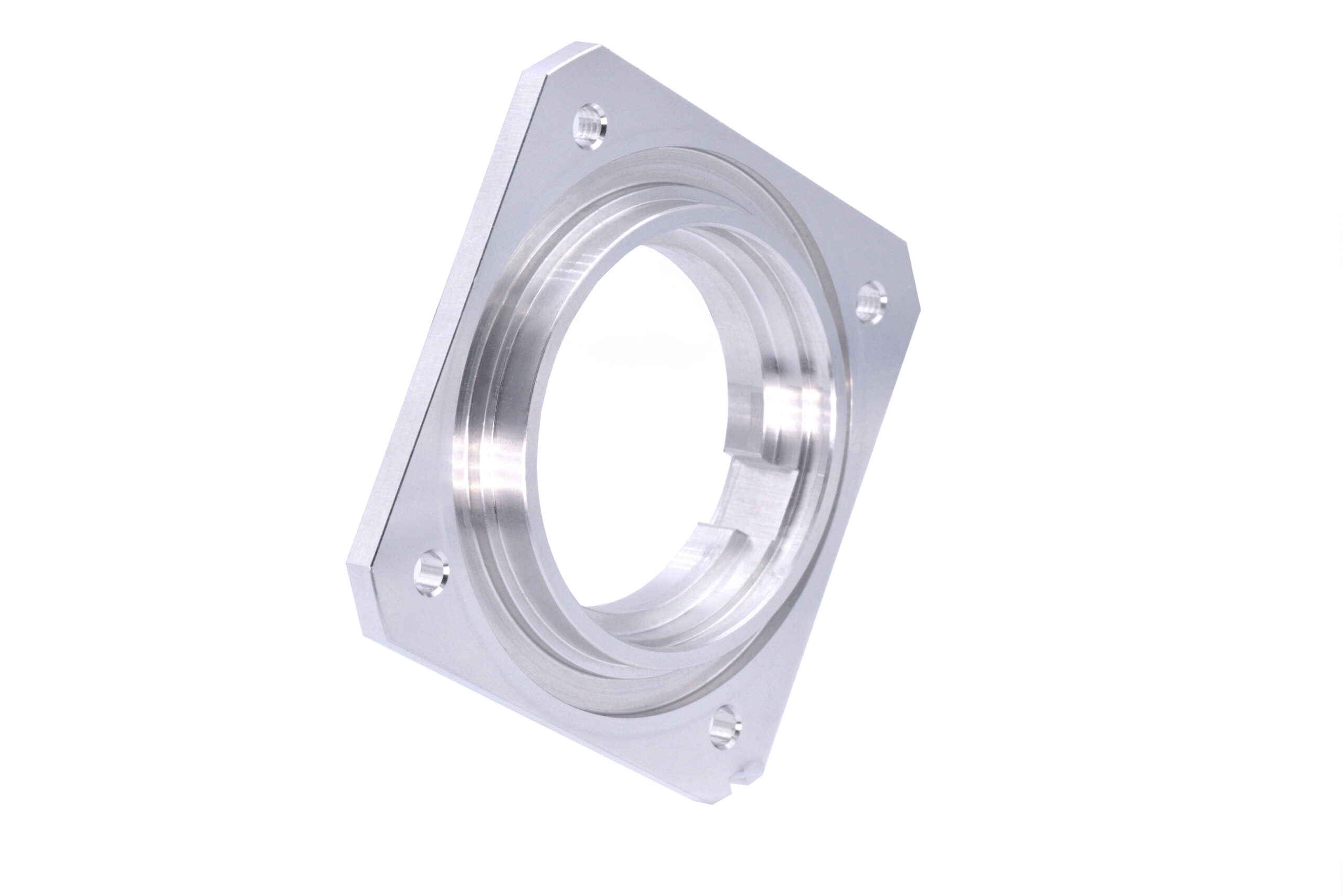

aluminium, copper alloy, copper, brass, celoron

CNC sliding headstock machines are mainly used in our workshop, however for the machining of certain types of connectors, we do use our fixed headstock machines.

We can handle the most complex shapes as we have machines with 10 numerical axes including B axes.

Our batch sizes vary according to your needs from 500 to 20,000 pieces and more.

We can machine all types of material such as aluminium, copper alloys, copper, brass or even celoron. See here the materials machined in our workshop.

Some examples of parts machined in our workshop: terminal blocks, connectors, adapters, sensor bodies, connection plugs, sockets, etc.

Additional services for connector machined parts

Through our network of subcontractors, we also provide additional services such as:

- Le Surface treatment: silvering, gilding, annealing

- Le Laser engraving

- Le Tribofinishing and deburring

We can also provide kit assembly services directly in our workshops.